How to troubleshoot CB4 V10 control board in WhatsMiner M30s?

How to Troubleshoot CB4 V10 Control Board in WhatsMiner M30s?

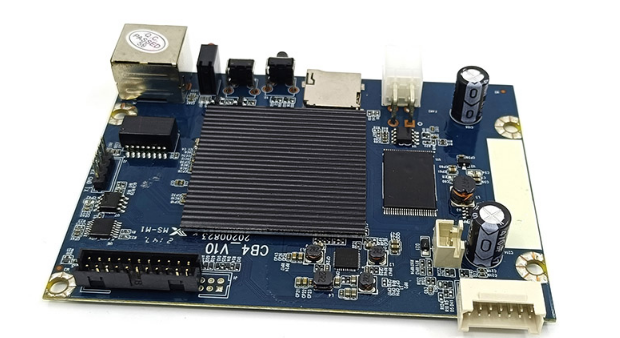

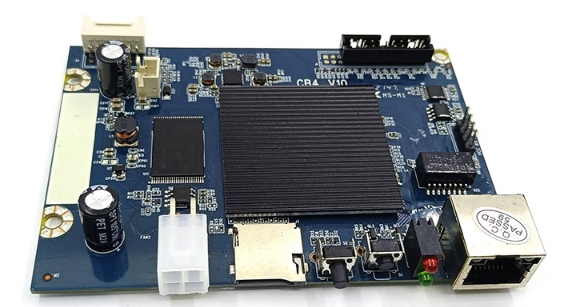

Cryptocurrency mining is a complex and demanding endeavor, requiring precise hardware coordination and optimal performance from every component. Among the critical elements in any mining setup is the control board, which serves as the operational hub for your mining rig. The CB4 V10 control board, specifically designed for the WhatsMiner M30s and other M-series models, is a professional-grade solution that ensures stability, efficiency, and reliability. However, even the most advanced hardware can encounter issues. This guide will walk you through practical steps to troubleshoot the CB4 V10 control board, helping you maintain peak performance and minimize downtime.

Introduction to the CB4 V10 Control Board

The CB4 V10 control board is a high-performance component engineered exclusively for WhatsMiner’s M-series mining hardware, including the M30s, M31s+, and M32 variants. Its robust design and advanced features make it an indispensable part of any professional mining operation. Key attributes include:

- Universal Compatibility: Seamlessly integrates with multiple WhatsMiner models, ensuring versatility across different setups.

- Industrial-Grade Reliability: Built with premium materials to withstand harsh mining environments.

- Optimized Performance Architecture: Delivers high hashrates while maintaining energy efficiency.

- Professional Connectivity: Features an IEC C19 16A power connection and Ethernet networking for stable operation.

- Thermal Excellence: Operates efficiently within a wide temperature range (-5°C to 35°C).

Despite its advanced design, the CB4 V10 control board may occasionally require troubleshooting to address operational issues. Let’s explore common problems and their solutions.

Common Issues and Troubleshooting Steps

1. Power Supply Problems

Symptoms: The miner fails to power on, or the control board shows no signs of activity.

Troubleshooting Steps:

- Check the Power Connection: Ensure the IEC C19 16A power cable is securely connected to both the control board and the power supply unit.

- Verify Power Output: Use a multimeter to confirm that the power supply is delivering the correct voltage (typically 12V or 220V, depending on your setup).

- Inspect for Damage: Look for burnt connectors or damaged cables. Replace any faulty components immediately.

- Test with Another PSU: If available, try using a different power supply unit to rule out PSU-related issues.

Preventive Tip: Regularly inspect power cables and connectors for wear and tear, especially in high-temperature environments.

2. Network Connectivity Issues

Symptoms: The miner cannot connect to the network, resulting in failed mining operations.

Troubleshooting Steps:

- Check Ethernet Cable: Ensure the Ethernet cable is securely connected to both the control board and the router.

- Test Network Port: Connect another device to the same Ethernet port to verify functionality.

- Restart Router: Power cycle your router to resolve potential network congestion or configuration errors.

- Update Firmware: Ensure the control board’s firmware is up-to-date, as outdated versions can cause connectivity issues.

Preventive Tip: Use high-quality Ethernet cables and keep your network infrastructure well-maintained.

3. Overheating

Symptoms: The control board shuts down unexpectedly, or performance drops significantly during operation.

Troubleshooting Steps:

- Monitor Temperature: Use the miner’s monitoring interface to check the temperature of the control board. If it exceeds 35°C, take immediate action.

- Improve Ventilation: Ensure adequate airflow around the control board and the entire mining rig. Consider adding additional fans or upgrading your cooling system.

- Clean Dust Accumulation: Remove dust and debris from the control board and surrounding components, as buildup can impede heat dissipation.

- Relocate Equipment: If ambient temperatures are too high, consider moving the mining rig to a cooler environment.

Preventive Tip: Regularly clean your mining setup and invest in a robust cooling system to prevent overheating.

4. Firmware or Software Glitches

Symptoms: The miner behaves erratically, fails to respond to commands, or displays error messages.

Troubleshooting Steps:

- Reboot the Miner: Power cycle the miner to resolve temporary software glitches.

- Reinstall Firmware: Download the latest firmware version from the manufacturer’s website and follow the installation instructions.

- Reset to Factory Settings: If the issue persists, perform a factory reset to eliminate corrupted configurations.

- Check Logs: Review the miner’s logs for error codes or unusual activity that could indicate the root cause.

Preventive Tip: Regularly update firmware to benefit from performance improvements and bug fixes.

5. Hardware Failures

Symptoms: The control board is unresponsive, or specific functions (e.g., hash rate monitoring) stop working.

Troubleshooting Steps:

- Inspect for Physical Damage: Look for burnt components, loose connections, or visible damage on the control board.

- Test with Another Board: If possible, replace the CB4 V10 with a spare control board to determine if the issue lies with the hardware.

- Contact Support: If the problem persists, reach out to WhatsMiner’s customer support for professional assistance.

Preventive Tip: Handle the control board with care during installation and maintenance to avoid accidental damage.

Practical Maintenance Tips for the CB4 V10 Control Board

To ensure the longevity and optimal performance of your CB4 V10 control board, follow these best practices:

- Regular Inspections: Periodically check the control board and its connections for signs of wear, damage, or dust accumulation.

- Keep Firmware Updated: Stay informed about firmware updates and install them promptly to benefit from the latest features and fixes.

- Maintain Optimal Cooling: Ensure your mining rig operates within the recommended temperature range to prevent thermal stress on the control board.

- Use Quality Components: Invest in high-quality power supplies, Ethernet cables, and cooling systems to support the control board’s performance.

- Document Issues: Keep a log of any issues and their resolutions to streamline future troubleshooting efforts.

Conclusion

The CB4 V10 control board is a cornerstone of the WhatsMiner M30s and other M-series mining rigs, offering unmatched reliability, compatibility, and performance. By understanding how to troubleshoot common issues—ranging from power supply problems to network connectivity glitches—you can maintain seamless operations and maximize your mining profitability.

Remember, proactive maintenance and regular inspections are key to preventing downtime and ensuring the long-term success of your mining endeavors. Whether you’re a seasoned mining operator or new to the industry, mastering the intricacies of the CB4 V10 control board will empower you to tackle challenges with confidence and keep your operations running smoothly.

Invest in quality, stay updated, and prioritize preventive care—your mining rig (and your bottom line) will thank you!