How to troubleshoot Antminer APW17 1215a power supply issues?-Antminer APW17 1215a Power Supply

Troubleshooting Antminer APW17 1215a Power Supply: Comprehensive Guide to Resolving Common Issues

Introduction to Power Supply Diagnostics

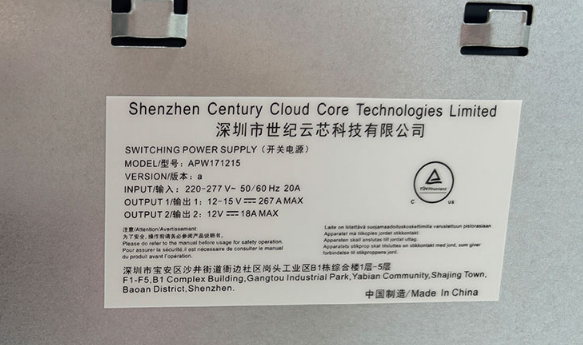

Cryptocurrency mining represents a complex technical ecosystem where power supply reliability is crucial. The Antminer APW17 1215a power supply unit stands as a critical component in high-performance mining operations, demanding meticulous maintenance and troubleshooting expertise. This comprehensive guide will provide in-depth insights into diagnosing and resolving potential power supply challenges.

Fundamental Diagnostic Approach

When encountering power supply issues with the Antminer APW17 1215a, a systematic diagnostic approach is essential. The following methodological framework ensures comprehensive issue identification and resolution:

1. Initial Symptom Assessment

Before diving into complex troubleshooting, carefully document and categorize observed symptoms:

– Complete power failure

– Intermittent power output

– Voltage instability

– Abnormal temperature readings

– Unexpected shutdown scenarios

2. Safety Precautions

Critical safety protocols must be followed during diagnostic procedures:

– Disconnect all power sources

– Use appropriate personal protective equipment

– Ensure proper grounding

– Work in a well-ventilated environment

– Utilize specialized electrical testing equipment

Detailed Troubleshooting Methodology

A. Voltage Regulation Diagnostics

The APW17 1215a’s sophisticated voltage regulation system requires precise evaluation:

Diagnostic Checklist:

– Verify input voltage consistency

– Measure DC output voltage range

– Check voltage stability under load

– Inspect voltage regulation components

Potential Diagnostic Tools:

– Multimeter

– Oscilloscope

– Professional electrical testing equipment

Recommended Measurement Parameters:

– Input Voltage: 220V ± 10%

– DC Output Range: 12V-15V

– Current Output: Maximum 267A

B. Connectivity and Interface Evaluation

Given the unit’s specialized C20 to P13 4-pin power cord configuration, interface integrity is paramount:

Inspection Criteria:

– Examine power cord connections

– Verify pin alignment

– Check for physical damage

– Test connectivity continuity

Common Interface Issues:

– Loose connections

– Corrosion

– Pin misalignment

– Damaged power cord segments

C. Thermal Management Assessment

The power supply’s thermal performance directly impacts operational reliability:

Thermal Diagnostic Procedures:

– Monitor temperature distribution

– Evaluate cooling system functionality

– Check ventilation pathways

– Inspect thermal interface components

Temperature Threshold Guidelines:

– Optimal Operating Range: 40-60°C

– Maximum Acceptable Temperature: 80°C

– Shutdown Temperature: >85°C

D. Power Conversion Efficiency Analysis

Efficiency measurements provide critical insights into power supply health:

Efficiency Evaluation Parameters:

– Power conversion ratio

– Energy loss measurements

– Performance under variable loads

– Comparison with manufacturer specifications

Diagnostic Indicators:

– Unexplained power consumption increases

– Reduced mining hardware performance

– Inconsistent power delivery

Advanced Troubleshooting Techniques

1. Component-Level Diagnostics

Systematic component-level testing enables precise issue identification:

– Capacitor condition assessment

– Voltage regulator module evaluation

– Power transistor performance analysis

– Circuit board integrity inspection

2. Software and Firmware Considerations

Modern power supplies incorporate sophisticated firmware:

– Check firmware version compatibility

– Verify update availability

– Perform controlled firmware reset

– Validate configuration parameters

3. Professional Diagnostic Equipment

Recommended Testing Instruments:

– High-precision multimeters

– Advanced oscilloscopes

– Thermal imaging cameras

– Power quality analyzers

Potential Resolution Strategies

When standard diagnostics reveal specific issues, targeted resolution approaches become critical:

A. Voltage Inconsistency

– Recalibrate voltage regulation circuits

– Replace damaged voltage regulation components

– Verify power source stability

B. Thermal Management Failures

– Clean cooling system components

– Replace thermal interface materials

– Enhance ventilation infrastructure

– Consider supplementary cooling solutions

C. Connectivity Problems

– Replace damaged power cords

– Recondition connection interfaces

– Verify grounding mechanisms

D. Component Degradation

– Identify and replace failing components

– Implement preventative maintenance schedule

– Monitor performance metrics

Preventative Maintenance Recommendations

1. Regular Inspection Protocols

– Monthly visual inspections

– Quarterly comprehensive diagnostics

– Annual component replacement assessment

2. Environmental Considerations

– Maintain stable operating temperature

– Control humidity levels

– Minimize dust accumulation

– Ensure proper ventilation

3. Performance Monitoring

– Implement continuous monitoring systems

– Track efficiency metrics

– Establish baseline performance indicators

Conclusion

The Antminer APW17 1215a power supply represents a sophisticated technological solution demanding expert-level maintenance. By implementing comprehensive diagnostic strategies, miners can optimize operational reliability, minimize downtime, and maximize mining infrastructure performance.

Success in cryptocurrency mining hinges on proactive technical management, with power supply reliability serving as a foundational element of sustainable mining operations.

|

Please feel free to contact me to assist you in resolving your issues: E-mail: Minerfixessales@gmail.com WhatsApp/WeChat:+86 15928044684

The services we offer include:

a.New and Used Miners b.Miner Accessories c.Miner Repair Courses d.Global Repair Stations e.Overclocking and Underclocking Services |

|