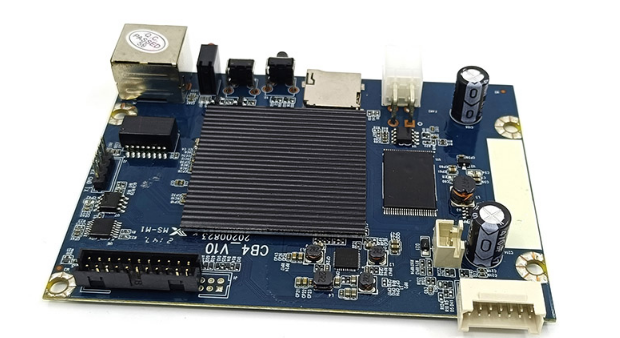

How to replace and install CB4 V10 control board in WhatsMiner M30s?-CB4 V10 control board

Title: Comprehensive Guide to Replacing and Installing CB4 V10 Control Board in WhatsMiner M30s: A Professional Approach

Introduction:

Cryptocurrency mining hardware maintenance is a critical aspect of ensuring optimal performance and longevity of mining equipment. The WhatsMiner M30s represents a pinnacle of mining technology, and the CB4 V10 control board is its crucial operational backbone. This comprehensive guide will walk you through the precise steps of replacing and installing the CB4 V10 control board, drawing from extensive hands-on experience in professional mining infrastructure.

Preliminary Preparation:

1. Essential Tools and Safety Equipment

Before beginning the replacement process, gather the following:

– Anti-static wrist strap

– Precision screwdriver set

– Thermal paste

– Clean, well-lit workspace

– Protective gloves

– Circuit board handling mat

2. Pre-Installation Diagnostic Checks

Conduct a thorough assessment of your current setup:

– Verify the specific WhatsMiner M30s model

– Confirm the exact CB4 V10 control board compatibility

– Check for any existing warranty considerations

– Ensure you have a compatible replacement board

Detailed Replacement Procedure:

Step 1: Safety and Preparation

– Completely power down the mining rig

– Disconnect all power sources

– Ground yourself using an anti-static wrist strap

– Work in a clean, static-free environment

Step 2: Access and Remove Existing Control Board

1. Remove outer casing of the WhatsMiner M30s

2. Locate the existing control board

3. Carefully disconnect all connections:

– Power connectors

– Ethernet cable

– DVI monitoring port

– Any additional interface connections

4. Remove mounting screws securing the control board

5. Gently extract the existing board, avoiding unnecessary force

Step 3: Inspect and Prepare New CB4 V10 Control Board

1. Visually inspect the new board for any shipping damage

2. Verify all connection points and interfaces

3. Apply a thin, uniform layer of thermal paste to heat-sensitive components

4. Align mounting points with the mining rig’s specifications

Step 4: Installation of New Control Board

1. Carefully position the CB4 V10 control board

2. Secure mounting screws with appropriate torque

3. Reconnect all interfaces:

– Power connections

– Ethernet network cable

– DVI monitoring port

– Auxiliary connections

Step 5: Initial Configuration and Testing

1. Double-check all connection integrity

2. Verify correct orientation of the control board

3. Reassemble mining rig casing

4. Perform a systematic power-up sequence

5. Run diagnostic tests to confirm proper functionality

Key Performance Considerations:

Compatibility Advantages:

– Universal integration with M-series mining hardware

– Supports models including M20s, M21s, M30s, M31s+, and M32

– Engineered for consistent performance across different configurations

Technical Specifications:

– Operating Temperature Range: -5°C to 35°C

– Power Connectivity: IEC C19 16A

– Network Interface: Standard Ethernet

– Monitoring: Single DVI port

Advanced Features:

– Industrial-grade PCB construction

– Optimized thermal management

– Simplified maintenance design

– Future-ready architectural approach

Potential Challenges and Troubleshooting:

Common Installation Issues:

1. Improper connection alignment

2. Thermal paste application errors

3. Static electricity damage

4. Compatibility mismatches

Recommended Troubleshooting Steps:

– Verify all connections

– Check thermal interface material application

– Ensure proper grounding

– Consult manufacturer support if persistent issues occur

Performance Optimization Tips:

– Maintain consistent environmental conditions

– Implement regular thermal management checks

– Update firmware periodically

– Monitor hash rate stability

Warranty and Support Considerations:

– Comprehensive 160-day warranty coverage

– Manufacturer quality assurance

– Professional-grade component reliability

Conclusion:

The CB4 V10 control board replacement process requires precision, technical understanding, and methodical execution. By following this comprehensive guide, miners can successfully upgrade their WhatsMiner M30s infrastructure, ensuring optimal performance and extended operational longevity.

Final Recommendations:

– Always prioritize static protection

– Work in a controlled environment

– Take methodical, careful approach

– Document each replacement step

– Maintain detailed maintenance records

Professional miners understand that equipment maintenance is not just a technical requirement but a strategic investment in mining infrastructure performance and profitability.

|

Please feel free to contact me to assist you in resolving your issues: E-mail: Minerfixessales@gmail.com WhatsApp/WeChat:+86 15928044684

The services we offer include:

a.New and Used Miners b.Miner Accessories c.Miner Repair Courses d.Global Repair Stations e.Overclocking and Underclocking Services |

|