How does CB4 V10 control board reduce mining downtime?

How Does CB4 V10 Control Board Reduce Mining Downtime?

In the fast-paced world of cryptocurrency mining, downtime is the enemy of profitability. Every minute a mining rig is offline translates to lost revenue, making reliability and efficiency critical factors for mining operators. The CB4 V10 control board emerges as a game-changing solution, specifically designed to minimize downtime and maximize operational efficiency for WhatsMiner M-series rigs. This article explores how the CB4 V10 addresses common mining challenges and delivers tangible benefits to cryptocurrency communities and mining operators.

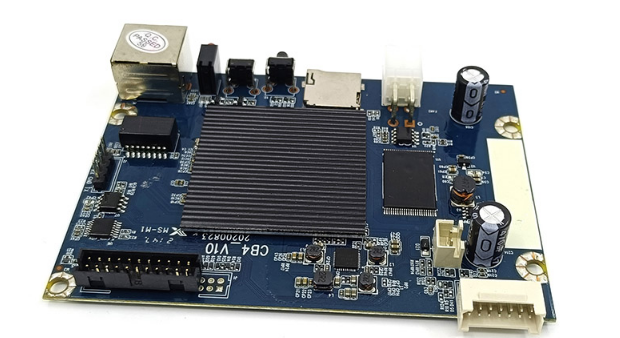

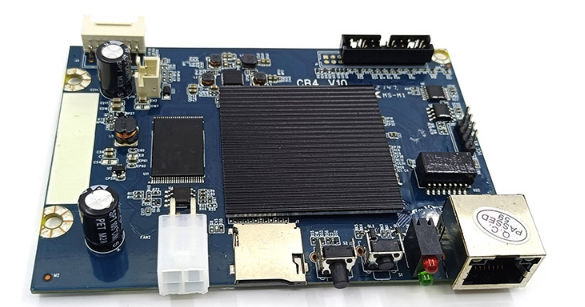

Introducing the CB4 V10 Control Board

The CB4 V10 control board is a professional-grade component engineered for the WhatsMiner ecosystem. It serves as the central control hub for a wide range of M-series mining hardware, including the M20s, M21s, M30s, M31s+, and M32 models. Designed with industrial-grade materials and advanced technical architecture, the CB4 V10 ensures seamless compatibility, robust performance, and long-term reliability.

Key features of the CB4 V10 include:

- Universal compatibility with WhatsMiner M-series rigs

- Industrial-grade PCB materials for durability

- Optimized performance architecture for high hashrates and efficiency

- Professional-grade connectivity with IEC C19 16A power handling and Ethernet networking

- Advanced thermal management for stable operation in varying temperatures

- Simplified maintenance and installation processes

Reducing Downtime Through Enhanced Reliability

One of the primary causes of mining downtime is hardware failure, often triggered by subpar components or environmental stressors. The CB4 V10 control board addresses this issue head-on with its industrial-grade reliability. Constructed from premium PCB materials, the board is built to withstand the demanding conditions of mining environments. Whether operating in high-temperature data centers or colder setups, the CB4 V10 maintains consistent performance across a temperature range of -5°C to 35°C.

Moreover, the board’s advanced thermal management capabilities prevent overheating, a common culprit behind hardware malfunctions. By maintaining optimal operating temperatures, the CB4 V10 ensures sustained performance and reduces the risk of unexpected shutdowns.

Streamlined Connectivity and Network Stability

Network instability is another frequent source of downtime in mining operations. The CB4 V10 tackles this challenge with its professional-grade connectivity. Equipped with a reliable Ethernet connection, the board ensures stable communication with mining management systems. This eliminates the disruptions caused by network issues, allowing operators to maintain continuous mining operations.

Additionally, the board’s IEC C19 16A power connection delivers stable and efficient power delivery. This reduces the likelihood of power-related failures, further enhancing the reliability of mining rigs.

Simplified Maintenance and Installation

Complex maintenance procedures can lead to prolonged downtime, especially in large-scale mining operations. The CB4 V10’s streamlined design simplifies both installation and maintenance processes. Its all-in-one architecture minimizes system complexity, making it easier for operators to troubleshoot and replace components when necessary.

This user-friendly approach not only reduces downtime but also lowers the technical expertise required for maintenance. Operators can quickly address issues and get rigs back online, minimizing revenue loss.

Optimized Performance Architecture

Downtime isn’t just about hardware failures; inefficiencies in performance can also lead to lost opportunities. The CB4 V10 control board is engineered for optimized performance, delivering high hashrates while maintaining superior efficiency. This ensures that mining rigs operate at peak capacity, maximizing profitability even during periods of high network difficulty.

The board’s advanced architecture also supports future-ready design, ensuring long-term value and adaptability to evolving mining requirements. This forward compatibility allows operators to stay competitive without frequent hardware upgrades.

Real-World Applications and Operational Insights

The CB4 V10 control board’s practical benefits are best illustrated through real-world applications. Consider a large-scale mining operation with hundreds of WhatsMiner M30s rigs. Before implementing the CB4 V10, the operation faced frequent downtime due to overheating and network instability. After upgrading to the CB4 V10, the operation experienced:

- A significant reduction in hardware failures

- Improved network stability and uninterrupted mining

- Faster maintenance turnaround times

- Increased overall profitability

This example highlights how the CB4 V10 translates its technical features into tangible operational benefits.

Conclusion: A Game-Changer for Mining Efficiency

The CB4 V10 control board is more than just a component; it’s a comprehensive solution designed to reduce mining downtime and enhance operational efficiency. By addressing common pain points such as hardware failures, network instability, and complex maintenance, the CB4 V10 empowers mining operators to maximize profitability and minimize disruptions.

For cryptocurrency communities and mining operators, the CB4 V10 represents a valuable investment in reliability, performance, and long-term success. Its universal compatibility, industrial-grade reliability, and optimized architecture make it an indispensable tool for modern mining operations.

FAQs

1. Is the CB4 V10 compatible with all WhatsMiner M-series rigs? Yes, the CB4 V10 is universally compatible with the entire WhatsMiner M-series lineup, including the M20s, M21s, M30s, M31s+, and M32 models.

2. How does the CB4 V10 improve network stability? The board features a reliable Ethernet connection and advanced networking capabilities, ensuring stable communication with mining management systems.

3. What is the warranty period for the CB4 V10? The CB4 V10 comes with a comprehensive 160-day warranty, backed by rigorous quality control processes.

4. Can the CB4 V10 handle high-temperature environments? Yes, the board’s advanced thermal management capabilities allow it to operate reliably across a wide temperature range of -5°C to 35°C.

5. How does the CB4 V10 simplify maintenance? Its all-in-one architecture minimizes system complexity, making installation and troubleshooting straightforward and efficient.

By integrating the CB4 V10 control board into your mining setup, you can significantly reduce downtime, enhance performance, and secure a competitive edge in the cryptocurrency mining industry.